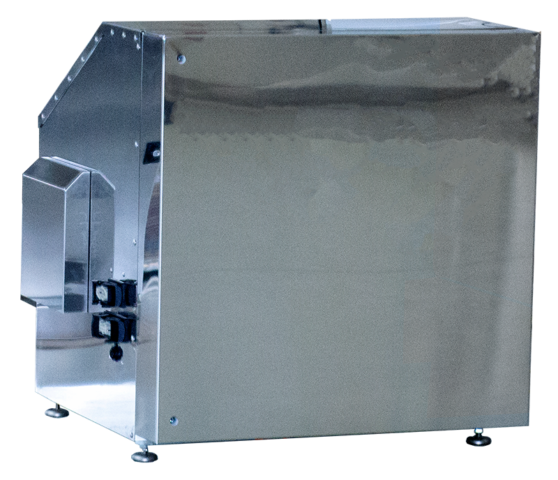

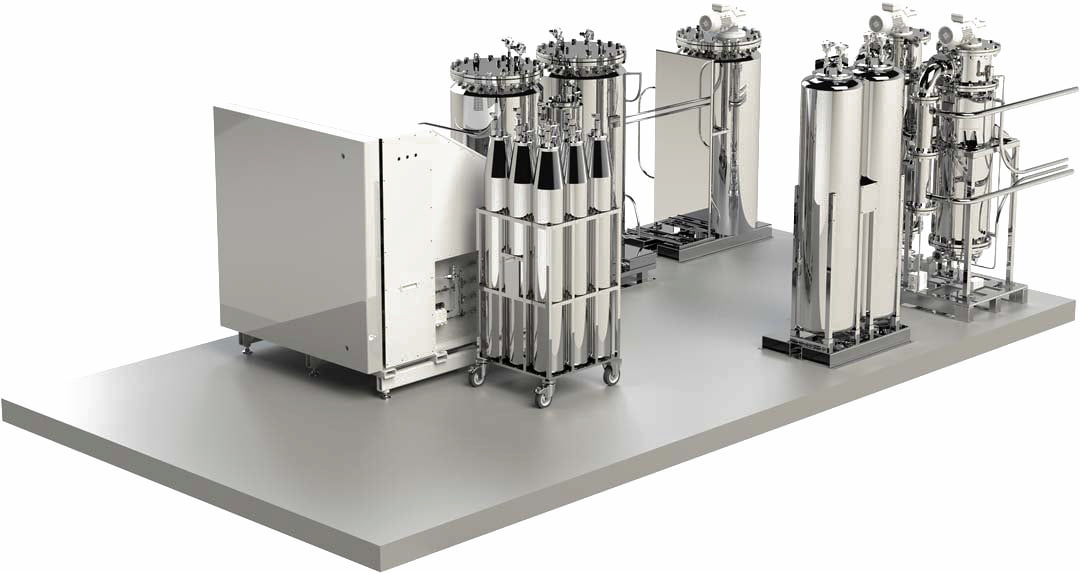

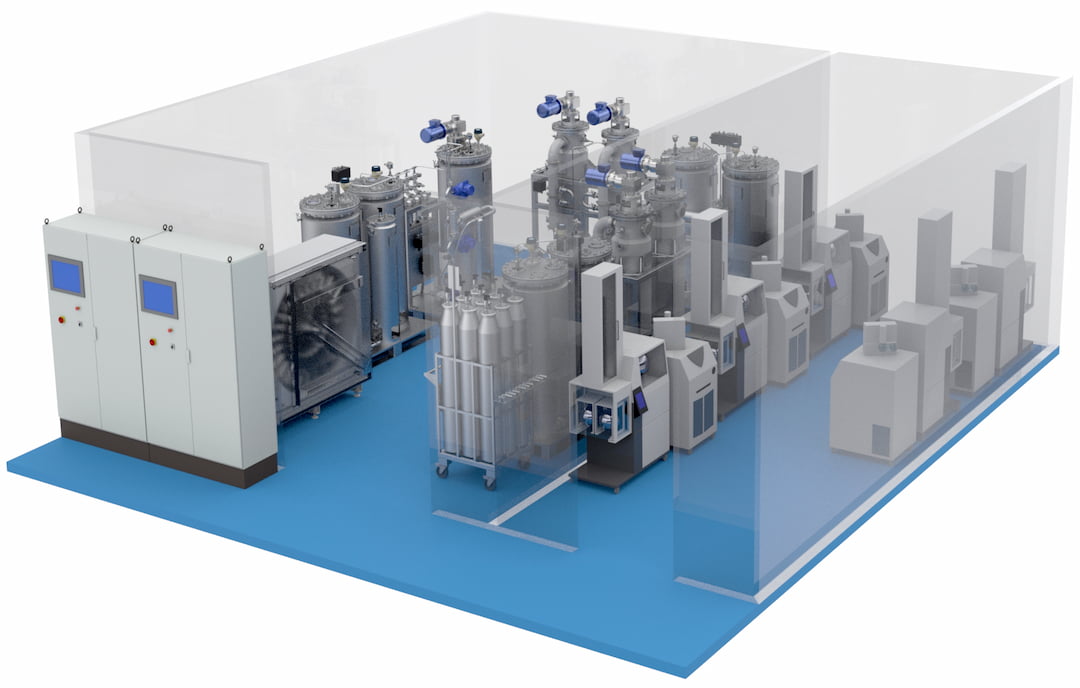

The CPC Modeler is a desktop-sized CPC platform, which combines an intuitive method development engine with tailor made semi-preparative chromatographic equipment. The CPC Modeler predicts, tests, and validates the most effective purification method of different Compounds of Interest (CoI), while also offering the possibility to scale-up production. The platform offers a mg to g/cycle loading capacity and can purify all the compounds that the rCPC can, including pharmaceutical APIs and natural extracts.

The platform comes with a GMP compliant software and digital toolkit, called the CPC Simulator. It is an individual tool, which lets you find the most effective CPC purification method and evaluate the productivity of your CoI, using the partition coefficient and the composition of your crude. The CPC Simulator uses an extended digital library, containing 16000 data entries from scientific publications, solvent systems, and chemical compound data to help you achieve your method-development goals.

Validate your digital purification setup with the provided semi-preparative partition chromatographic equipment. Test your purification method on the benchtop CPC system, and fine-tune your operational parameters for optimal performance. Deliver you purified materials through the chromatographic process, and see the results of the in-silico purification method in real life.

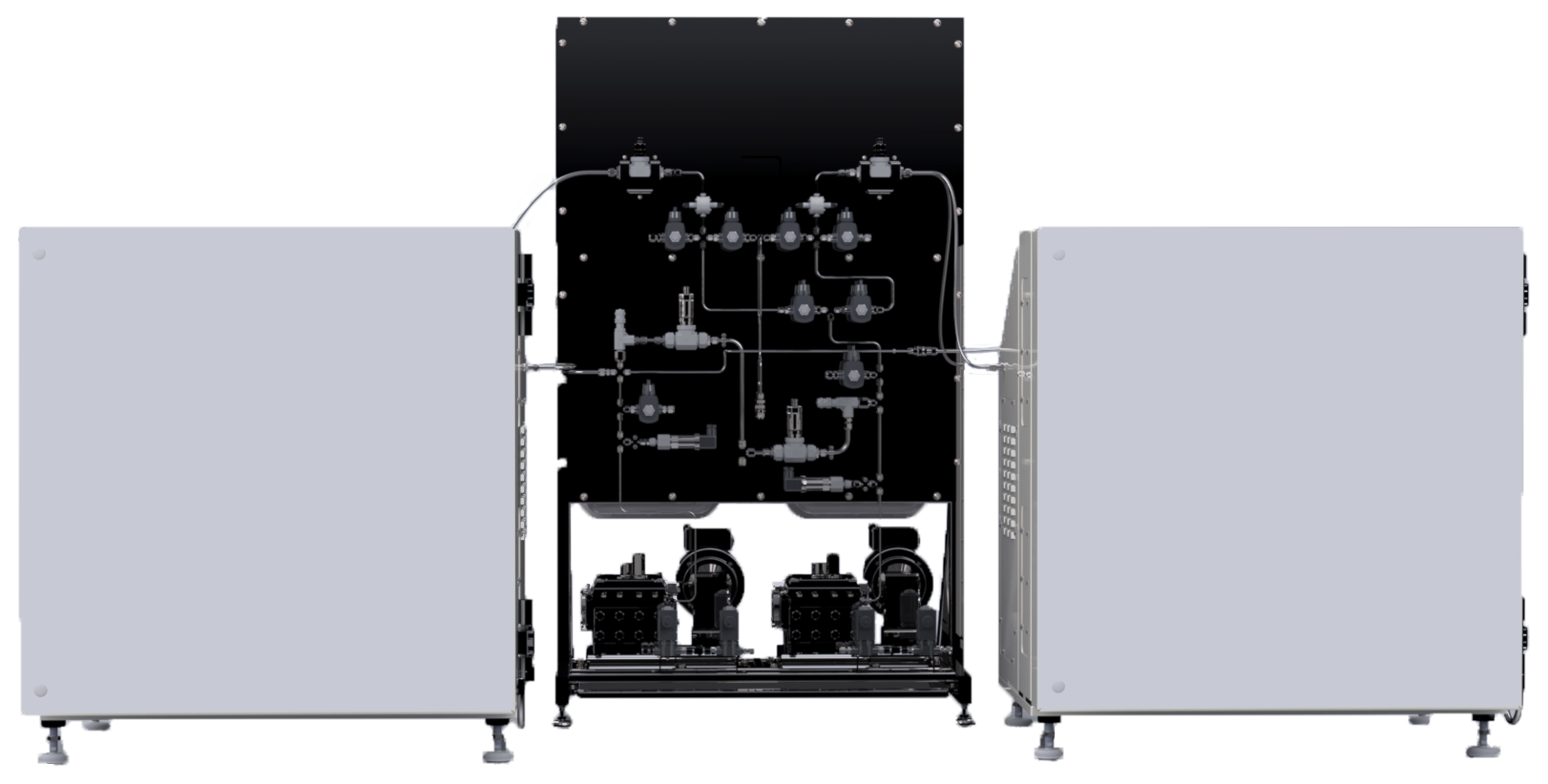

The CPC Modeler is compliant to a variety of standards, such as ASME/BPE and GAMP, CFR 21 Part 11. Sanitary design includes 316L SS wetted flow path, FDA conforming non-metallic parts. Electrical and safety approvals are CE/UK CA/NRTL.