Optimizing Recombinant Human Albumin Isolation with Centrifugal Partition Chromatography

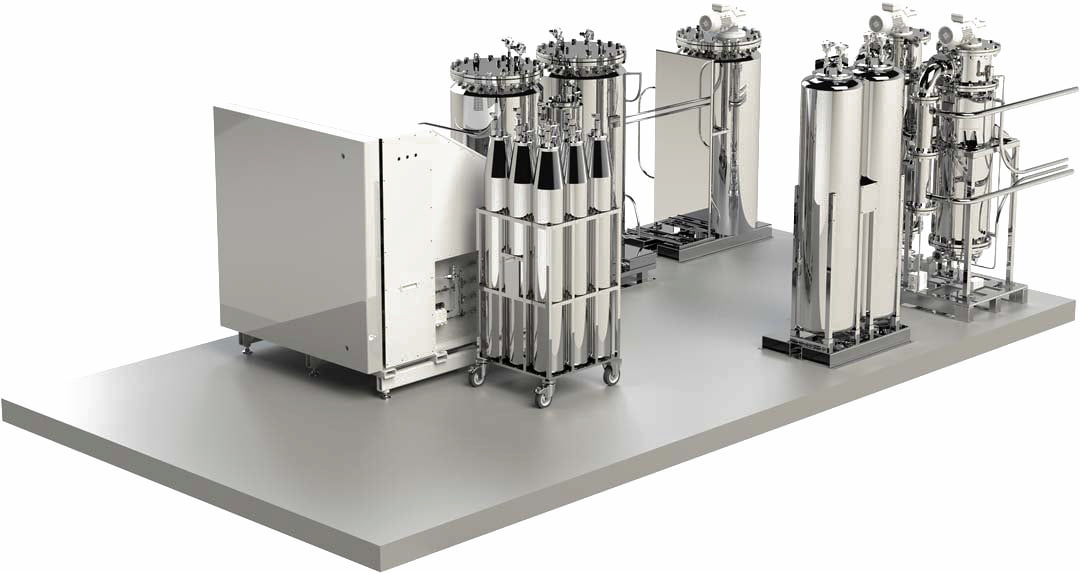

Education, NewsThe pCPC unit is comprised of the RotaChrom iCPC instrument and a Skid system which automates the purification process, from solvent preparation to recycling under ex-proof environment. RotaChrom’s pCPC platform offers high throughput, outstanding purity, increased yield and cost efficiency compared to current alternative purification platforms.