Chemspec 2025 – A Recap

Conferences, Exhibitions, NewsRotaChrom offers a wide range of solutions to meet your business needs and help you boost your performance. Our one-of-a-kind CPC technology is at the heart of our devices, which we use in all of our products. Our portfolio covers everything from in-silico method development and laboratory-scale purification to pilot-scale, industrial-scale and continuous CPC. RotaChrom’s cell design and the traits of CPC technology ensure that your individual purification method can be easily scaled-out to exactly what your business needs, and you won’t have to invest into multiple technologies.

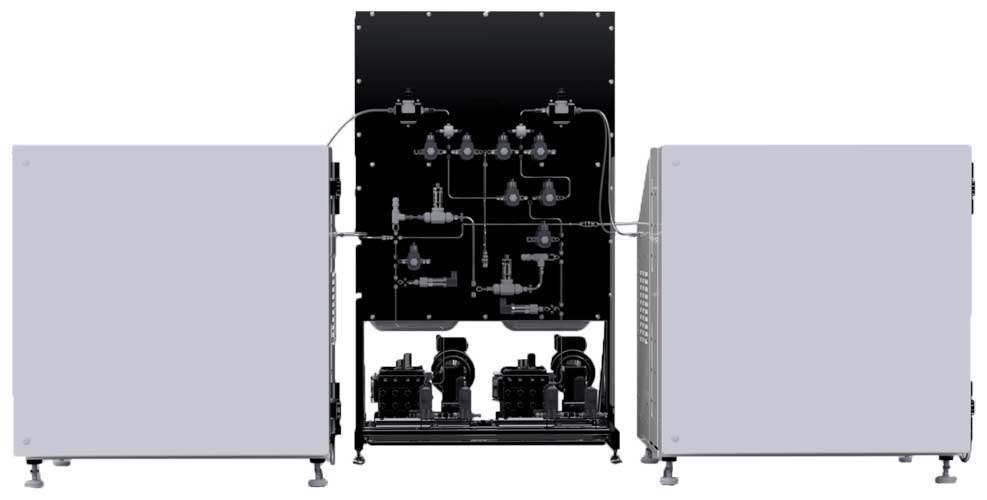

We understand that specific tasks often require specific tools. This is why we support our partners with flexible prices and tailor-made configurations based on unique input provided by the business partner. Add-ons for RotaChrom devices are available, whether you need solvent handling, or polishing a final product, just to name a few applications. RotaChrom’s unique devices are ready to tackle any challenge they face.