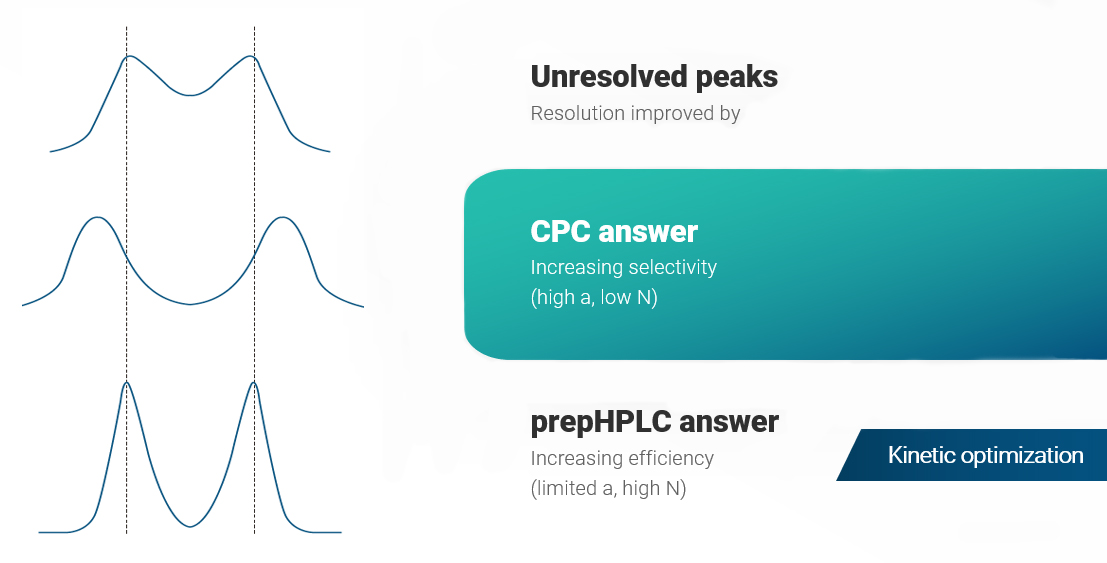

While other chromatography designs are capable of higher resolution output, they rapidly incur costs. Furthermore, the high-end machines required for other methods are extremely sensitive to breaking and have limited solvent availability.

The strength of CPC technology lies in its robustness when compared to other methods. With a durable and reliable design, it can power through the pressure barriers that restrict other methods from industrial-scale purification.

Instead of relying on one method versus another, CPC can easily fit into the procedures of other methods. As an analogy, traditional methods can be thought of as a knife, while CPC is an axe. Although the knife is more effective when making a precise cut, in some applications — chopping wood to make furniture, for example — the axe would be a more effective tool. However, after cleaving the large volume of wood, the finer blade is better suited to carving the details.

Similarly, CPC effectively prepares samples upstream before traditional chromatography methods finish the job, reducing costs and time since you don’t have to rely solely on high-cost, slow chromatography to purify bulk samples from beginning to end. Our CPC platforms save cost, simplify product development and increase throughput with robust chromatography.

CPC technology can be used in a wide range of chemical productions as most involve some kind of purification or separation steps. And while it requires more steps to develop effective methods than other techniques, the benefits are worthwhile as CPC outperforms other methods in terms of efficiency and flexibility. This level of freedom allows you to adjust your solvents precisely to achieve a highly efficient and selective output.

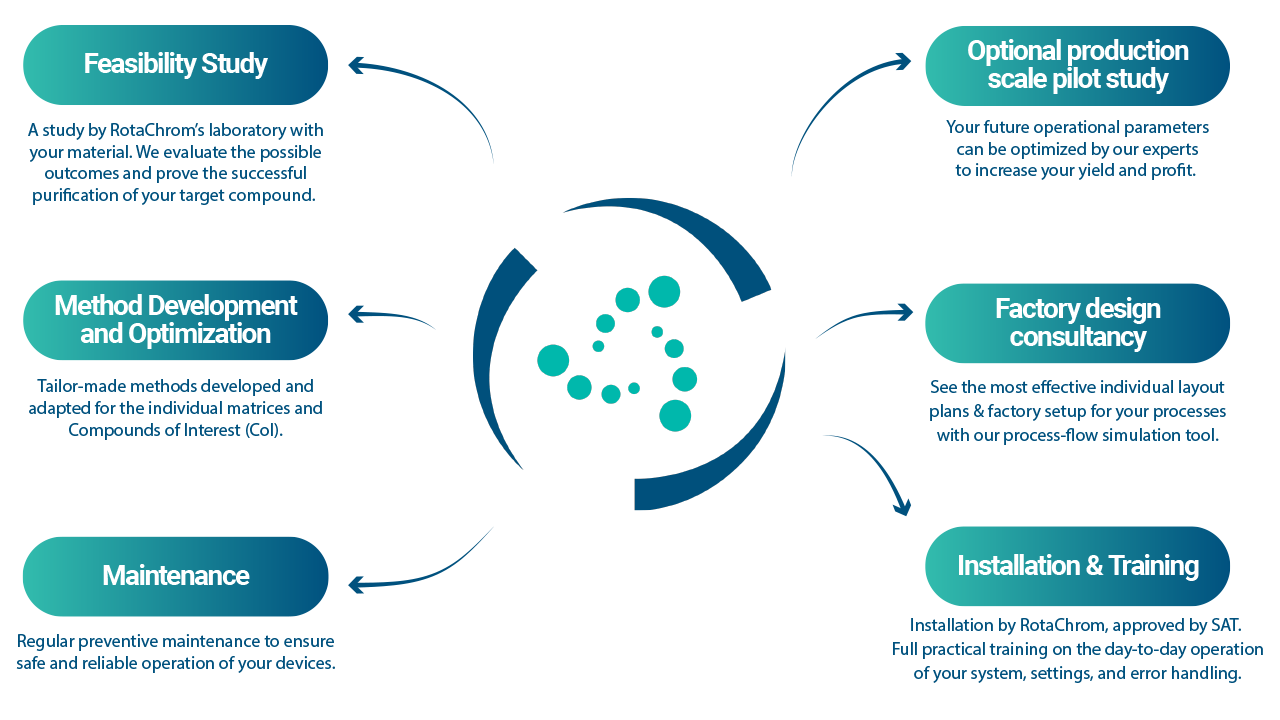

We don’t just sell an isolated instrument, we evaluate your whole process to find the best placement for our product. CPC is compatible in many downstream extraction, distillation, evaporation or crystallization techniques. For example, coupling CPC technology with olive oil bioactive component recovery yields greater purities and enables higher productivity. Combining chemical reaction and separation steps by integrating CPC with equilibrium-limited hydrolysis applications can also reduce manufacturing times as well as solvent and energy costs.

In addition to providing a novel instrument, we offer design and consultation services from start to finish and take pride in offering the most cost-effective purification solutions on the market.

Do you want to know more about the differences between the common preparative techniques and centrifugal partition chromatography (CPC technology), or when is CPC a good solution? Are you interested in a total cost of ownership evaluation? Fill out the form and learn more!

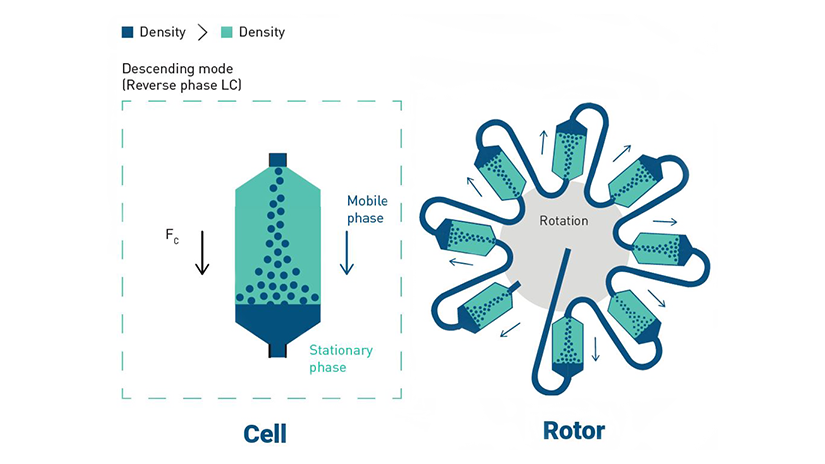

Competing CPC separation techniques are limited by the pressure rises that come with any increase in production volumes. Above a certain flow rate, especially when using high viscosity solvent systems, these techniques meet their maximum allowable operating pressure and prevent the system from delivering higher flow rates, resulting in a pressure plateau and preventing further volume scaling without negative consequence. However, our system can overcome the pressure barrier. In fact, we have yet to even meet our pressure barrier.

We also optimized our centrifugal system for higher flow rates with lower pressures of 70 to 80 bars, facilitating flows of 2 liters per minute and more. With the ability to operate at higher pressures up to 120 bars, our separation is more efficient and achieves higher resolutions than competing preparative chromatographic techniques.

Besides a cell design optimized for minimum pressures, CPC technology provides excellent stationary phase retention, further increasing loadability and reducing operating costs relative to other preparatory methods.