Chemspec 2025 – A Recap

Conferences, Exhibitions, News‘Advanced Chromatography’ is our mini-series about more in-depth chromatographic topics, and a continuation of ‘An Introduction to Chromatography’. Last time we looked at the basics of Centrifugal Partition Chromatography (CPC) and the specifics of CPC cell design. This time we’ll examine the operating modes of a CPC device and see why ascending and descending modes make these platforms more versatile.

CPC Methodology Recap

In CPC, conventional chromatographic columns are swapped to cells. These cells (columns) are interlinked in series by ducts connected to a large rotor filled with the liquid stationary phase. The liquid contained in this sequence of cells can then be immobilized inside the rotor by a strong centrifugal force.

The other phase of the two-phase CPC system is used as the mobile phase containing the sample to be purified. It is introduced into the rotor under pressure and pumped through the stationary phase in the form of tiny droplets.

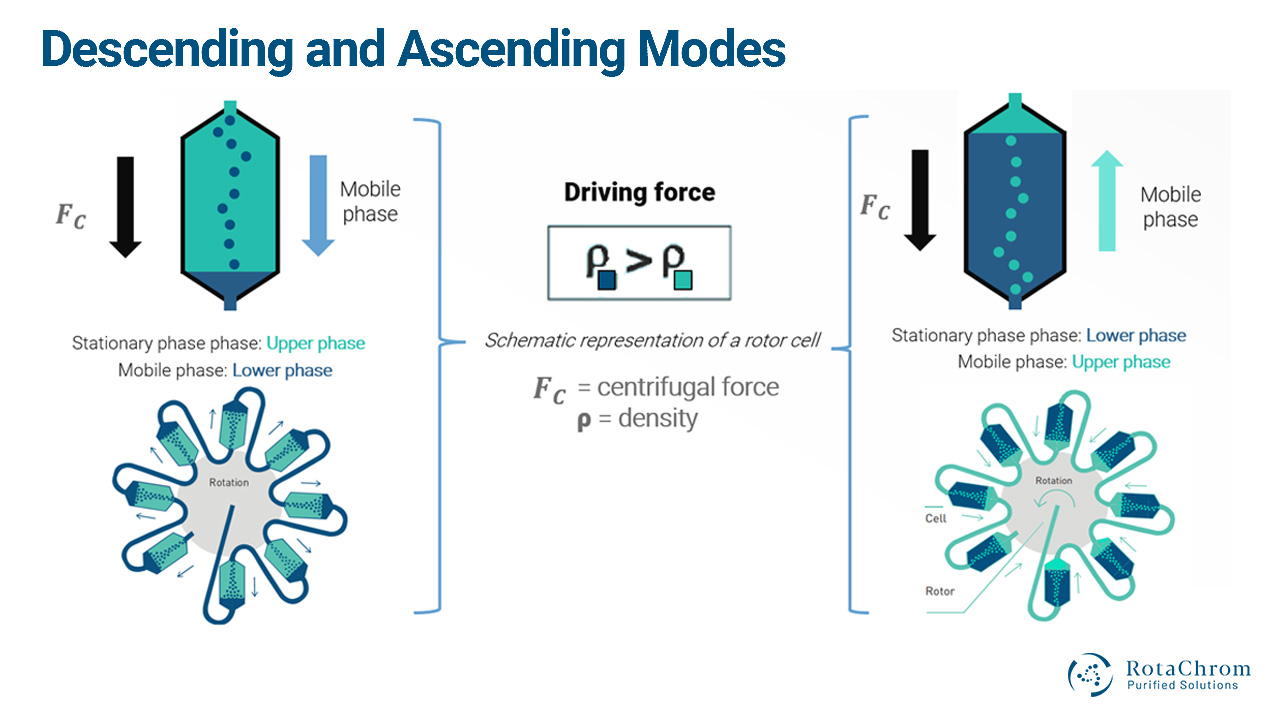

A valve allows for a switch in the direction of flow and thus the CPC system will work in either ascending mode, where the lighter phase is the mobile phase, or in descending mode when the heavier phase is used as the mobile phase.

Ascending & Descending CPC Modes

To examine the operating modes of a CPC device, we’ll take RotaChrom’s technology as an example. The column in a RotaChrom CPC machine is the rotor and the interconnected cells. This is the feature which gives way to the different methods of operation. Namely, the CPC device can be operated in two different modes:

- Ascending mode

- Descending mode

The main factor which decides the mode is the density of the mobile phase.

This is because a liquid mobile phase can be denser or less dense depending on the separation. The mobile phase’s density is of course in comparison to the density of the immobilized stationary phase. This means that the mobile phase must be denser or less dense than the stationary phase.

When using the ‘ascending’ mode, the mobile phase is the less-dense phase of the two phases. When this is the case, the direction of the flow becomes the opposite of the centrifugal force. When operating the machine in ‘descending’ mode, then the mobile phase becomes the denser phase. Typically, operating in descending mode gives better separation.

Operating a RotaChrom CPC device in both modes is possible. However, certain devices require more preparation than other ones. In the case of rCPC, one machine can be operated both ways. It doesn’t need any extra parts or preparations. For the iCPC, however, the rotor must be switched depending on the mode you want to run it in. You need a different rotor for the ascending mode, and another one for the descending mode. However, the iCPC device itself otherwise can be the same.

Daily operation of an rCPC device

Daily operation of the rCPC consists of 3 types of methods in a defined order.

- The start method – filling the rotor with stationary phase, concurrently speeding up the rotor to operation speed. When the system is ready, (rotor has reached the defined rotational speed and is filled with the stationary phase completely) start method is followed by

- The loop method – injection of the sample material to the system, followed by elution with mobile phase and finished with extrusion using stationary phase. The loop method is set up to be used for production – without having to stop, it could be repeated infinitely.

- The process is completed with the Stop method – stopping the rotation of the rotor followed by stopping of the pump.

Further information

Further information

If you are interested in more in-depth Centrifugal Partition Chromatography resources, we recommend checking RotaChrom’s website:

Want to get in touch?

Fill in the form below so our representatives can contact you. We will also let you in on more information on our technology.