Optimizing Recombinant Human Albumin Isolation with Centrifugal Partition Chromatography

Education, NewsClick a link below to navigate to section on page

Pharmaceutical Applications

Click a link below to navigate to section on page

Pharmaceutical Applications

Cosmetics & Fragrances

Food & Beverages

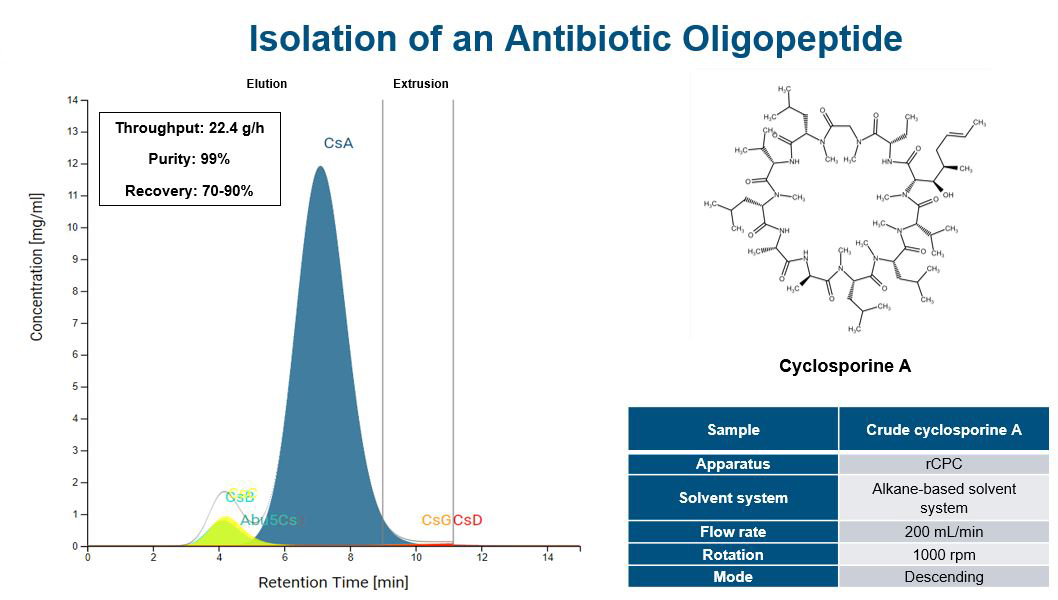

Active Pharmaceutical Ingredient (API): Cyclosporine A (CsA)

Goal: Purification

Cyclosporine A is a cyclic oligopeptide, with a lipid side-chain. It is produced by fermentation. The result of fermentation is usually a mixture of products with closely related structural properties. These are usually purified by classical purification methods: a combination of crystallization and preparative HPLC. To avoid costly two-step purification methods, RotaChrom developed a CPC solution which can produce pure Cyclosporin in 15 minutes on an industrial- scale.

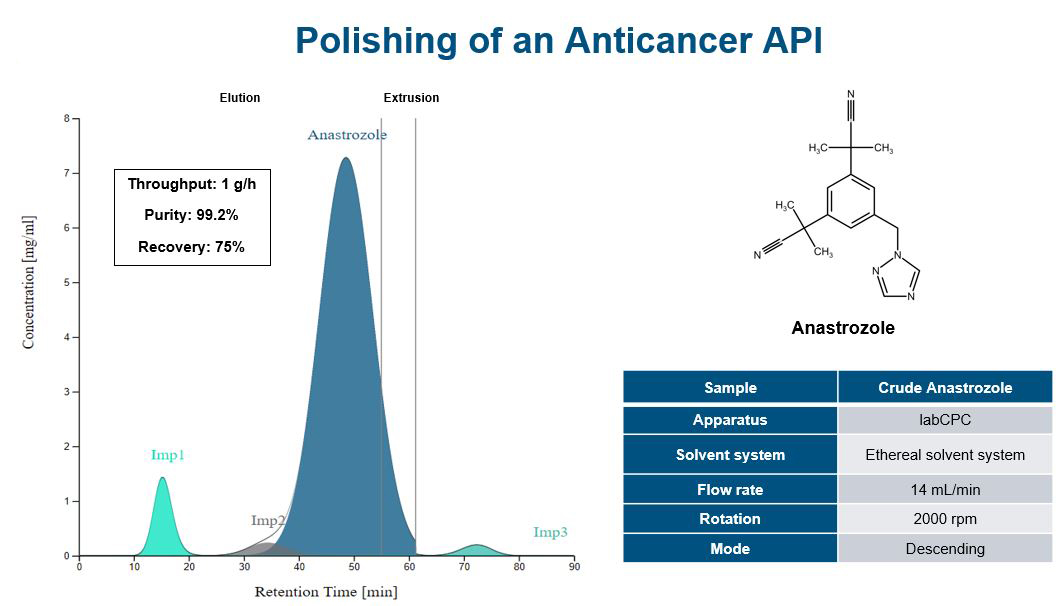

API: Anastrozole

Goal: Polishing the API

Anastrozole is a pharmaceutically active agent, acting as a selective nonsteroidal aromatase inhibitor. Guidelines for API manufacturers mention that impurities must be kept below set limits. The study’s goal was to replace a purification step which needed column chromatography. At the end of the study, RotaChrom’s method could produce Anastrozole with higher than 99% purity, all in one step. After CPC purification, >99.9% purity can be achieved in a single crystallization step.

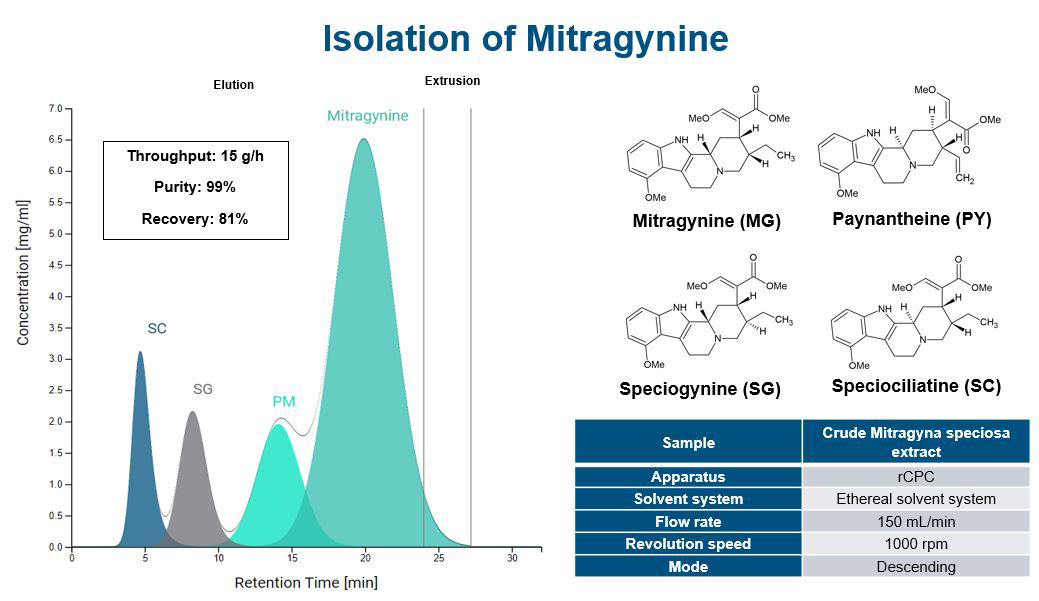

Compound of Interest (CoI): Mitragynine

Goal: Isolation of the CoI

This compound is a major alkaloid in Mitragyna speciosa leaf extract. Closely related alkaloids are also present in the extract besides mitragynine. These include speciogynine (SG), speciociliatine (SC) and paynantheine (PM). CPC isolated mitragynine from samples cost-effectively with as high purity (99%) compared to other techniques. The developed method could purify directly from the crude extract. In addition, the process needed fewer steps, and it turned out to be more economical than traditional solutions.

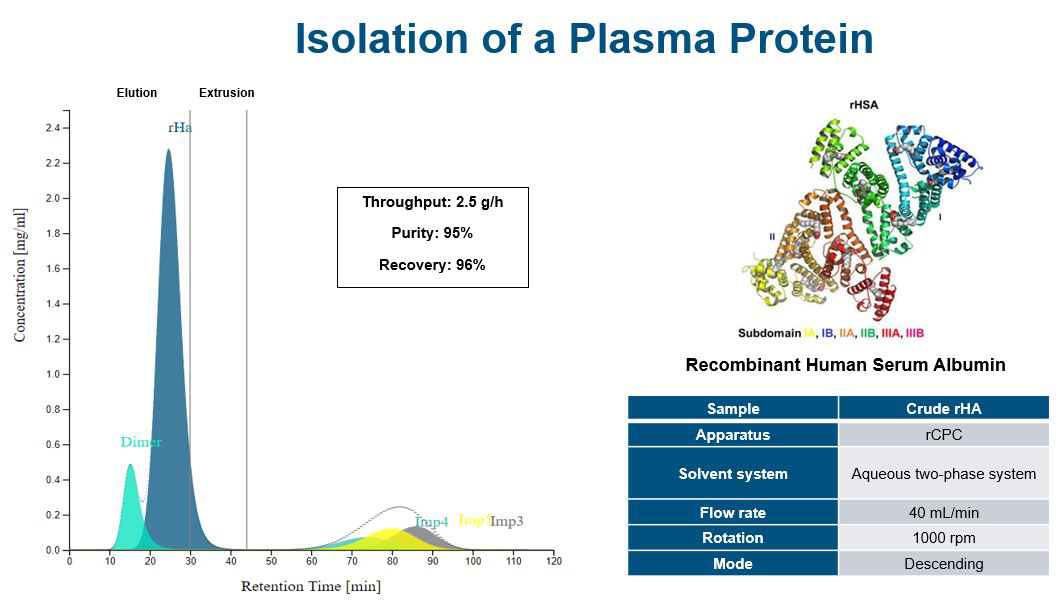

CoI: Recombinant Human Albumin (rHA)

Goal: Isolation of the CoI

To this day, the Cohn method is the most widely used core fractionation technique. However, it comes with high initial investment and maintenance cost. At the end of the study, the resulting rCPC method could isolate rHA with higher than 95% purity and high recovery.

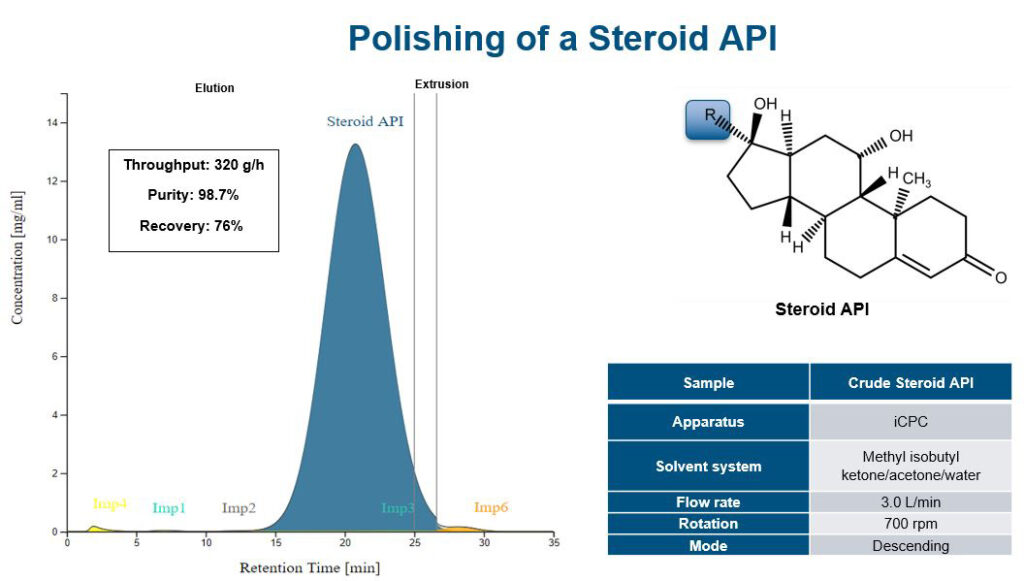

API: Steroid

Goal: Purification

A microbiological fermentation process produces this API. However, if reaction selectivity is compromised, stereoisomer of the API and other by-products appear in the process. Conventional production techniques of this API require steps that result in a significant loss of the yield. During the last step only, which is a preparative HPLC step, the loss is 70%. Using our CPC method, a yield of above 90% can be achieved with the similarly high purity. Because of the remarkable selectivity value, the system can be loaded well despite the low solubility of the API.

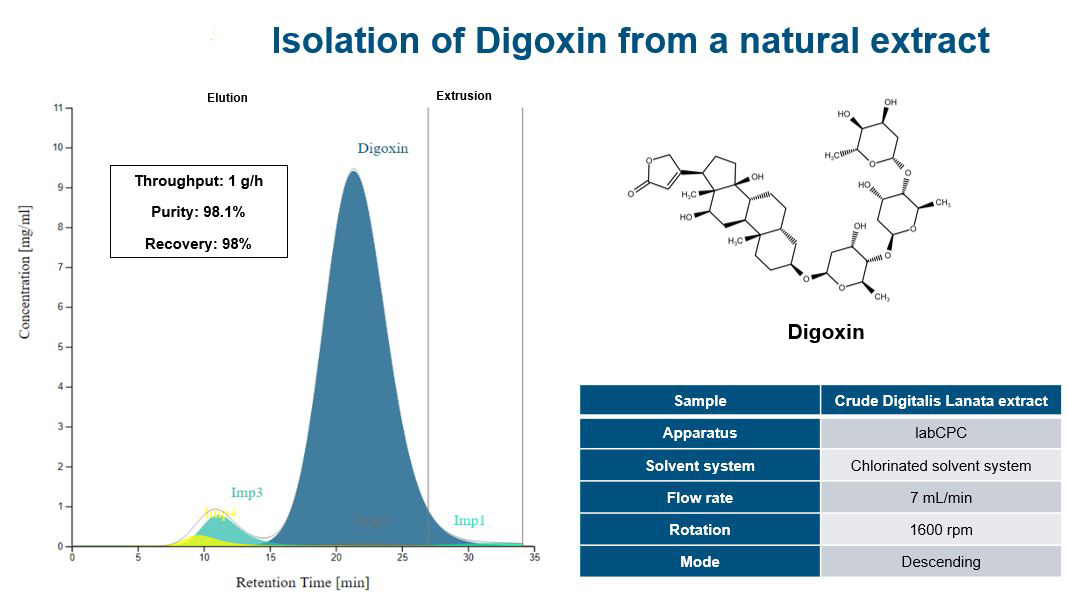

CoI: Digoxin. A secondary cardiotonic glycoside isolated from the fermented foliage of foxglove (Digitalis lanata).

Goal: Isolation

High-value bioactive compounds are usually surrounded by compounds of similar structure. These are often difficult to be isolated in their pure forms. Digoxin’s mono- and bisdigitoxosides, digoxigenin and gitoxin were the main impurities that needed remediation. At the end of the study, we separated Digoxin directly from the crude extract.

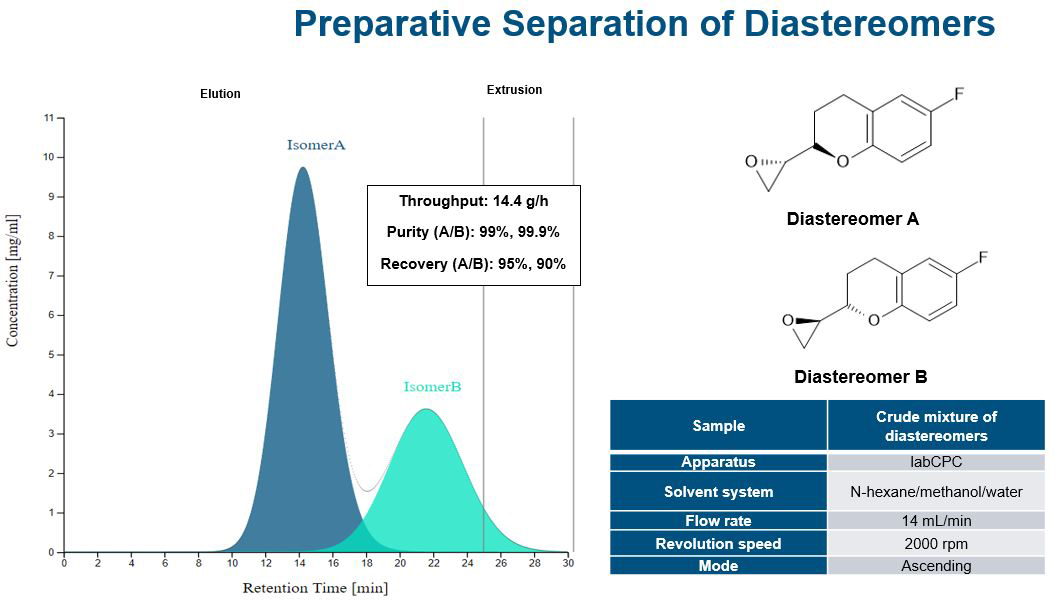

CoI: Benzopyrene compound

Goal: Separation

Diastereomers of an optically active substance are similar in structure, but show significant differences in pharmacodynamic properties. This benzopyrene compound is a precursor for a ß1 receptor blocker drug. The sample consisted of about 57% isomer A and 31% isomer B. We achieved high purity and recovery for both diastereomers. Running the rotor in ascending mode further encouraged the recovery of products.

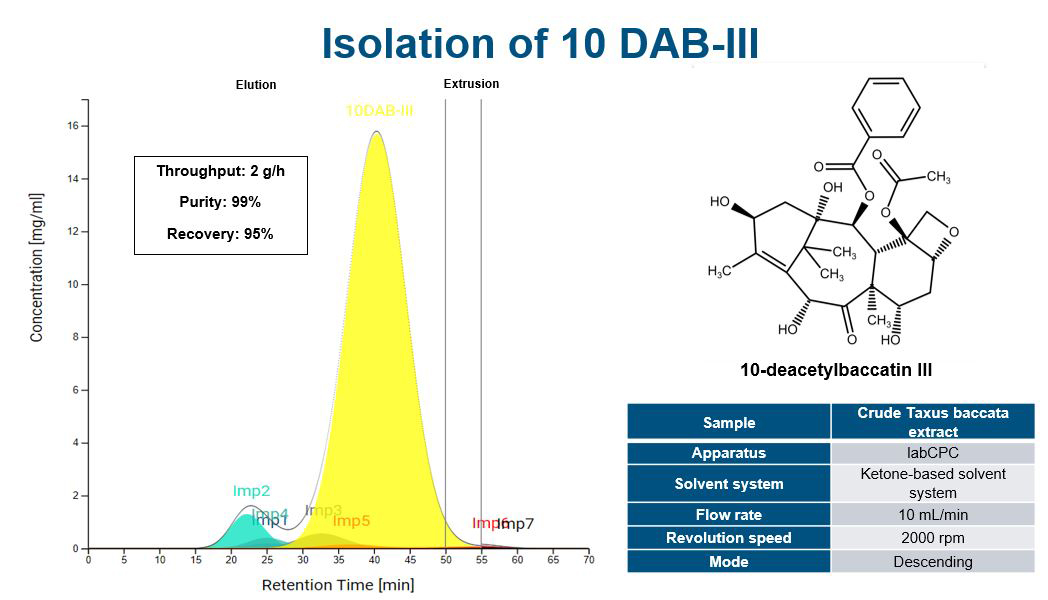

CoI: 10 DAB-III from Taxus baccata extract.

Goal: Isolation

Docetaxol is a taxane diterpenoid, used as a chemotherapeutic drug. It is prepared from 10-DAB III by a semi-synthetic method. The crude extract contained a large amount of co-extractives along the taxanes of interest. Therefore, a purification step was needed to remove them. Our CPC method isolated 10 DAB-III with excellent purity and yield, and offered an efficient and cost-effective solution for purification on a large scale.

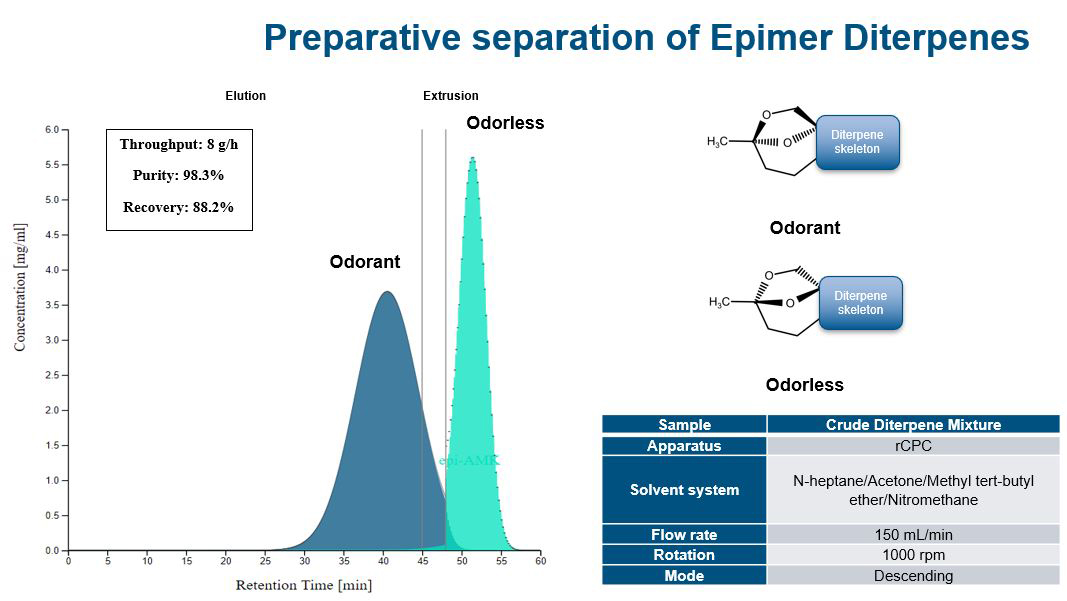

Goal: Separation of epimers

Ratio of epimers in the starting material: 7:3

The Compound of Interest is a synthetically produced perfume ingredient. It’s important to note that this separation was yet to be solved cost-effectively by either column chromatography or fractional distillation. The selectivity value between the CoI and its epimer (1.59) in the selected solvent system is unprecedentedly high in the field of small molecule and chromatographic epimer separation. Selectivity of this scale typically requires chiral stationary phase, which adds significant additional costs.

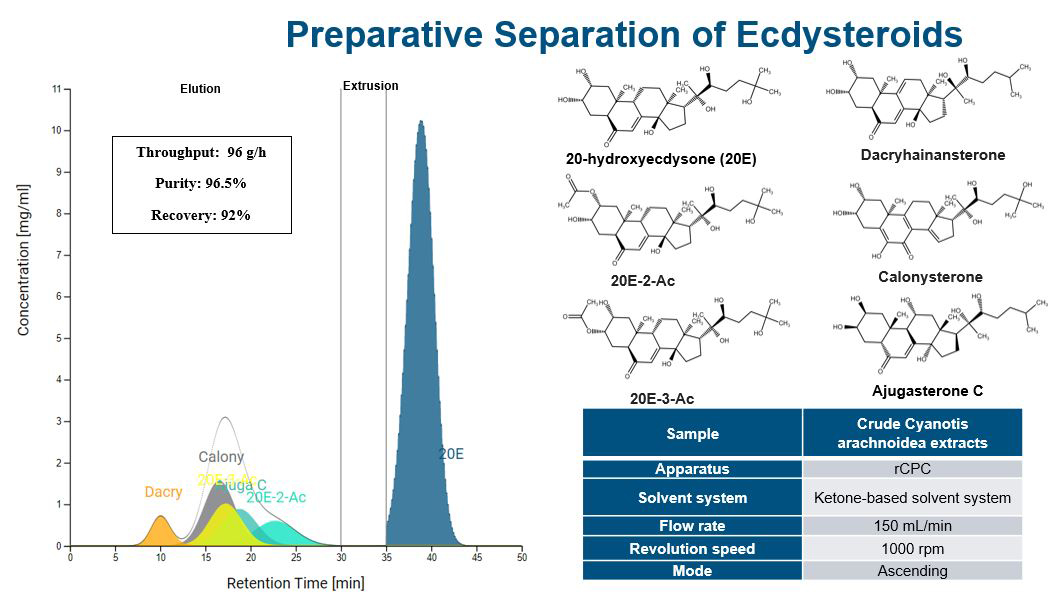

Starting Material: Ecdysteroid-rich Cyanotis arachnoidea extracts

Goal: Isolation and purification

The most abundant phytoecdysteroid in the extract is 20-hydroxyecdysone (20E). It’s widely used in dietary supplements, so the primary goal was to isolate it from the extract. Other components in the sample were minor ecdysteroids such as dacryhainansterone (Dacry) and calonysterone (Calony) and its acetate derivatives. Our CPC method achieved remarkable selectivity for 20E. This means our technology can isolate 20E with excellent purity and recovery.

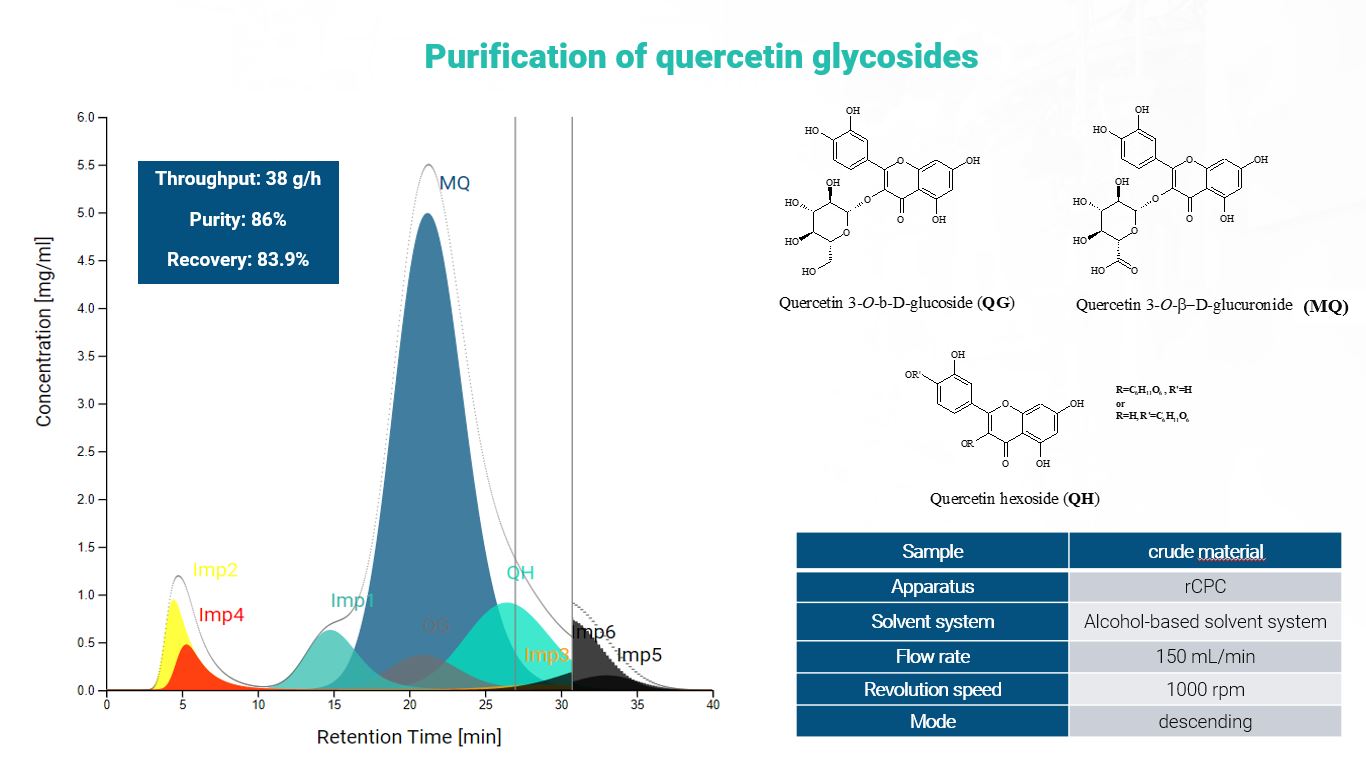

Goal: Separation

The separation task was to investigate the feasibility of the isolation of quercetin glycosides. The primary objective was to achieve a purity value greater than 75% by weight for quercetin-3-β-O-D-glucoside (QG) quercetin-3-O-β-D-glucuronide (MQ) and a quercetin hexoside (QH) using food-grade solvents.

After extraction the developed CPC method was capable of isolating the three target compounds together with purity greater than the expected. It had a high throughput using only food grade chemicals. The end product could be re-crystallized from water which could further increase purity.

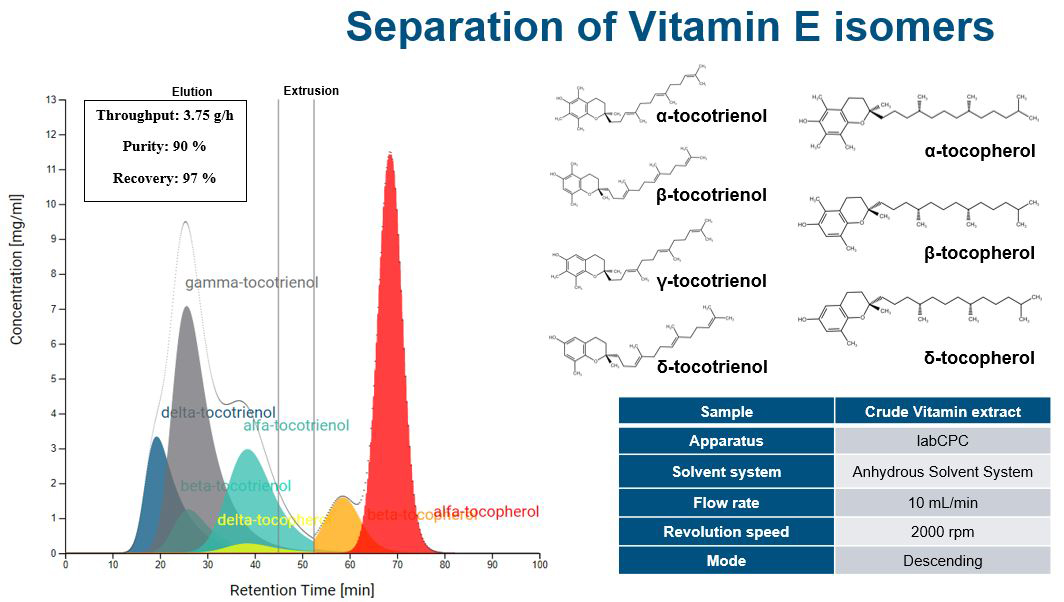

CoI: Tocotrienols and Tocopherols (members of the vitamin E family)

Goal: Separation

The oil included vitamin E isomers such as α-tocopherol, α-tocotrienol, β-tocopherol, β-tocotrienol, γ-tocotrienol, δ-tocopherol and δ-tocotrienol. Our CPC method could fractionate tocotrienols and tocopherols with excellent loading capacity: 50 ml injected volume to a 250 ml rotor. It achieved high selectivity for both the individual tocotrienols and tocopherols. The new method applied an anhydrous solvent system, which facilitated the recovery of the end product after the CPC run.

Latest News

Webinars

Contact Us

RotaChrom Technologies LLC (Headquarters)

Csillag street 2/A, Kecskemet, HU-6000

+36 70 885 6922

RotaChrom North America Inc.

300 Spectrum Center Drive, Irvine, CA 92618

+1 (720) 220-5669