Increasing separation efficiency by pH adjustment in Centrifugal Partition Chromatography

NewsSince the earliest days of chromatographic methodologies emerging, novel techniques have been developed that all offer various benefits to their users. Numerous different techniques exist for material purification, and it can seem overwhelming to understand all the different methods in existence. Flash chromatography has been a staple in material purification for many years. While flash chromatography is a reliable and widely used method, there may be other techniques that offer additional benefits for specific businesses.

CPC vs Flash Chromatography

There are several questions you need to ask when selecting the right purification method:

- Efficiency: How quickly can the desired compounds be separated and purified?

- Cost: Is the method cost-effective, both in terms of the equipment needed and the amount of solvents and other consumables used?

- Scale: Can the method be used on a small or large scale, depending on the needs of the business?

- Versatility: Can the method be used to purify a wide range of compounds, or is it only suitable for a narrow range of applications?

Centrifugal partition chromatography (CPC) and flash chromatography are both relatively affordable and easy-to-use alternatives to traditional column chromatography. However, they do have their own specific strengths and weaknesses that may make one method more suitable for a particular application.

- CPC is known for its high separation efficiency and ability to handle large sample volumes. It can also be used to purify a wide range of compounds, including lipids and natural products.

- Flash chromatography is known for its simplicity and versatility. It can be used to purify a wide range of compounds, and is also relatively easy to scale up or down, depending on the needs of the business. However, it is not as efficient as CPC and may require the use of larger amounts of solvent.

Ultimately, the choice between CPC and flash chromatography will depend on the specific needs of the business, including the type of compounds being purified, the available equipment and resources, and the scale of the operation.

Flash chromatography

It is true that flash chromatography doesn’t need expensive equipment to operate, but there are some aspects which do ramp up its operational costs. One of the main expenses associated with flash chromatography is the cost of the separation column, which is typically filled with silica gel. Silica gel is a porous material that is used to adsorb and separate compounds based on their size and charge. It is a consumable material that needs to be replaced regularly, and the cost of the gel can add up over time.

Another factor to consider is the cost of the flash cartridge, which is the container that holds the separation column. Flash cartridges come in various sizes and configurations, and the cost can vary depending on the brand and the size of the cartridge. It’s important to choose a cartridge that is suitable for the volume of sample and the amount of solvent needed for the separation, as using a larger cartridge than necessary can increase the cost unnecessarily.

Overall, while flash chromatography is a relatively affordable and easy-to-use method, it is important to factor in the ongoing costs of the separation column and flash cartridge when evaluating the total cost of using this method.

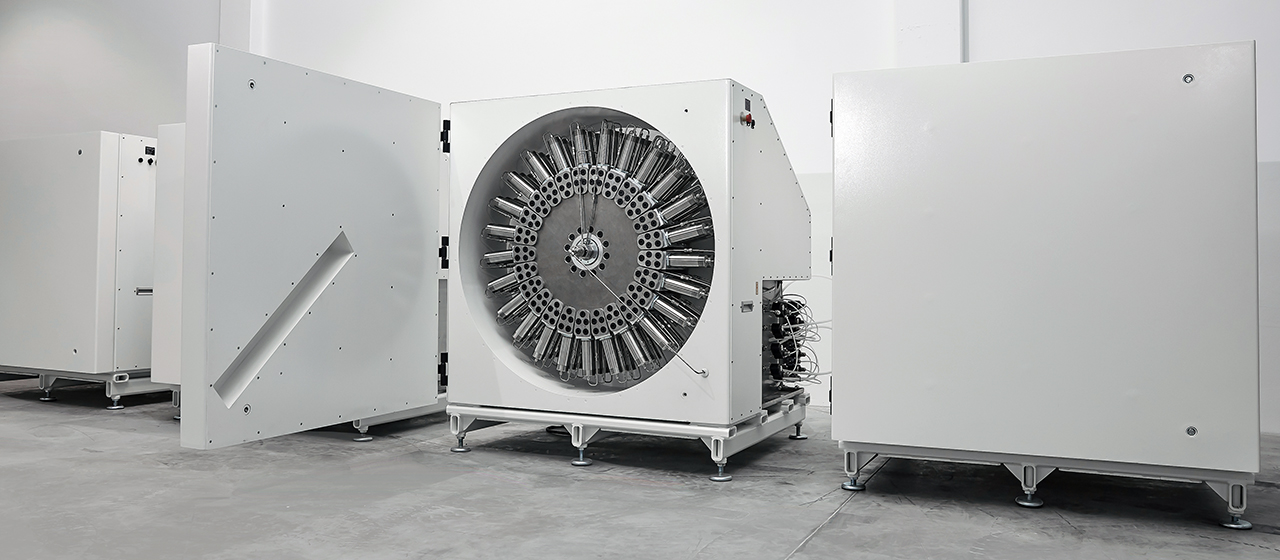

Centrifugal Partition Chromatography

Centrifugal Partition Chromatography, however, avoids both of these issues, lowering its operational expenses by a large amount. How this is done is through the technology that powers CPC, which is liquid-liquid chromatography.

In liquid-liquid chromatography, separation occurs between two immiscible liquid phases, without the need for a solid stationary phase like silica gel. This makes it a cost-effective alternative to methods like flash chromatography, which requires regular replacement of the silica gel. Centrifugal partition chromatography (CPC) is a particularly efficient liquid-liquid chromatography technique, with high yield and purity compared to traditional chromatographic methods. With CPC, there is little risk of sample loss or degradation due to interaction with the column, and the columns can be reused after rinsing, leading to less waste and lower expenses. Additionally, RotaChrom’s individual cell design simplifies the scale-up process, a common challenge in traditional chromatographic applications.

Application Example

But don’t just take our word for this. We have several demonstrations proving the validity of our special centrifugal partition chromatography solution.

Polishing of an anticancer API

API: Anastrozole

Goal: Polishing the API

Usually, a microbiological fermentation process is used to produce this API. However, reaction selectivity is compromised by the stereoisomer of the API, and other by-products also appear during the process. The large number of steps during production result in a low overall yield. Just in the final step, which is a preparative HPLC step, the loss is 70%.

In contrast, with our Centrifugal Partition Chromatography technique, a yield of above 90% could be achieved with the same purity as in the case of the conventional methods. Plus, due to the high selectivity, a large amount of sample can be loaded into the system, despite the low solubility of the API. In addition, RotaChrom’s individual cell design eliminates the time consuming and painstaking scale-up procedures, characteristic of traditional chromatographic applications.

Would you like to learn more?

If this sparked your curiosity about centrifugal partition chromatography, we invite you to take a look at our other resources:

Want to get in touch?

Fill in the form below so our representatives can contact you. We will also let you in on more information on our technology.