Increasing separation efficiency by pH adjustment in Centrifugal Partition Chromatography

NewsIn “An Introduction to Chromatography’, we examine the essentials and main aspects of chromatography. We started with the very basics (e.g. defining chromatography itself) and then worked our way up towards more complex topics. Finally, as we wrap up the series, we arrived at Centrifugal Partition Chromatography basics. Our goal is to make chromatography easy to understand, so that anyone can get a grasp of the subject. So, exactly what is CPC?

So far, we learned many different aspects of chromatography. We examined the downstream process, and chromatography process steps. We learnt what a chromatogram is, and what fraction collection means. This week we will learn the most important elements of Centrifugal Partition Chromatography (CPC).

Are you a chromatography expert already? If so, we have many advanced resources available for you. Click the button to learn more!

Basics of Centrifugal Partition Chromatography

Basics of Centrifugal Partition Chromatography

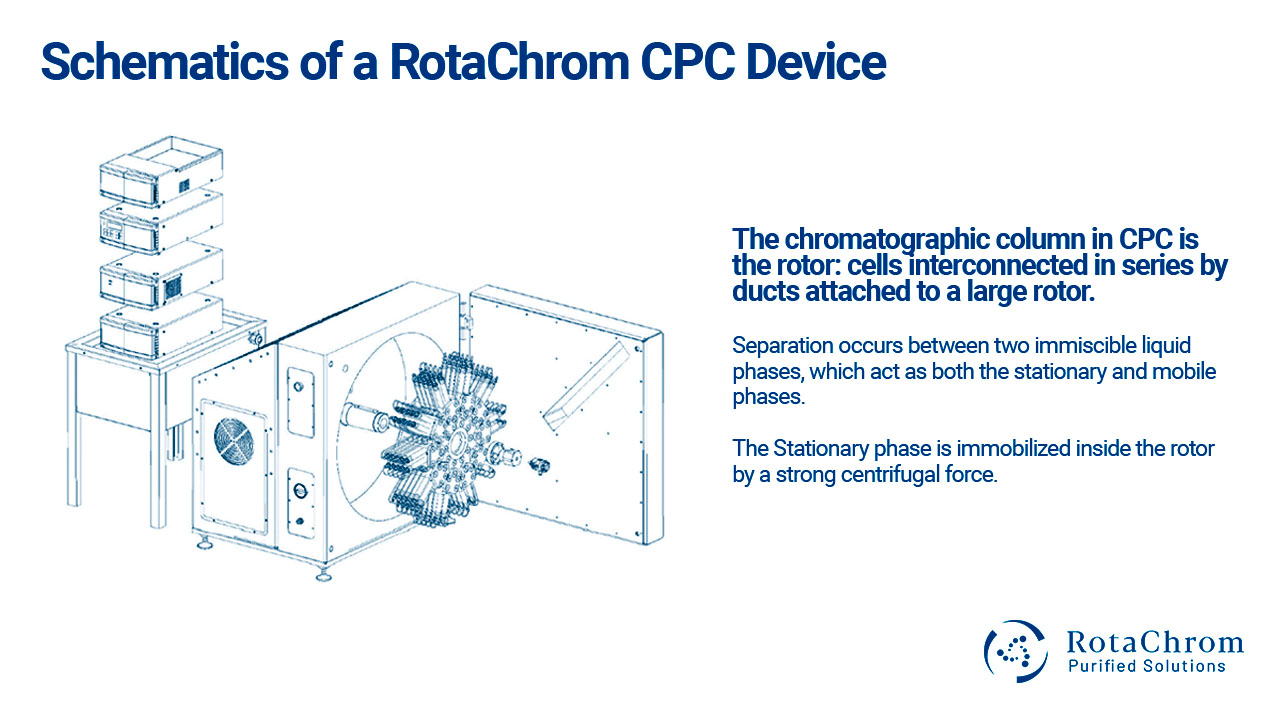

Centrifugal Partition Chromatography (CPC) is a liquid-liquid preparative chromatographic technique, in which separation occurs between two immiscible liquid solvent systems: acting as both the stationary and mobile phases. Separation of the injected sample is based on the sample component’s varying partition coefficients between the mobile and stationary phases. Partition coefficient (Kd) is the equilibrium constant for the distribution of a compound in a two-phase system.

To make use of this technique, a pattern of CPC cells (columns) are interconnected in series by ducts attached to a large rotor. This system is then filled with the liquid stationary phase, which is immobilized inside the rotor-cell system by a strong centrifugal force. The other phase of the two-phase system is used as the mobile phase containing the sample which is going to be purified. This liquid is fed under pressure into the rotor and pumped through the stationary phase in the form of tiny droplets.

There are several core advantages of Centrifugal Partition Chromatography over classical, solid support-based preparative liquid chromatograph. Two examples are:

- simplicity of separation mechanism – easy method development and scale-up

- high loadability and recovery – no sample loss due to irreversible adsorption; (iii) no need for solid stationary phase and medium solvent consumption – cost effectiveness.

But, of course, there are several other benefits, and you can learn about them on our website.

RotaChrom’s CPC solutions

RotaChrom has developed a revolutionary preparative purification instrument called Industrial Scale Centrifugal Partition Chromatographic (iCPC) device. This novel system does not utilize any solid stationary phase (such as silica gel) to achieve precision molecular separation and is demonstrably superior to conventional liquid chromatographic techniques in terms of yield and purity. In addition, the iCPC platform has radically reduced the costs and number of steps associated with downstream method development for a diverse array of purification challenges.

Like conventional liquid chromatography, separation of the injected sample is based on the sample component’s varying partition coefficients between the mobile and stationary phases. The partition coefficient dictates the amount of time each molecule spends within the mobile and stationary phases and therefore the rate at which each molecule travels through the system. At the end of the purification process automated fraction collectors retain all selected fractions based on the program settings.

RotaChrom designed its top performing CPC cells through Computational Fluid Dynamic simulation software. After thousands of simulations, this tool revealed the drawbacks of conventional CPC cell designs and highlighted the unparallel load capacity and scalable cell design of RotaChrom.

If you’re curious about CPC technology, take a look at RotaChrom’s Technology page which will give you a head-start in the topic.

Want to get in touch?

Fill in the form below so our representatives can contact you. We will also let you in on more information on our technology.