Increasing separation efficiency by pH adjustment in Centrifugal Partition Chromatography

NewsNew Partnership Aims to Develop More Efficient, Cost-Effective Process to Purify Remdesivir.

RotaChrom announced the launch of a collaboration with Cyclolab Cyclodextrin Research and Development Laboratory Ltd. (“Cyclolab”), a cyclodextrin research, development and manufacturing company. The strategic partnership between Cyclolab and RotaChrom aims to develop a more efficient and cost-effective process to purify Remdesivir, which is a widely used treatment option for COVID-19.

Remdesivir, an inhibitor of the viral RNA-dependent, RNA polymerase, is a direct-acting antiviral agent that is approved by the FDA as a treatment for patients with severe cases of COVID-19. It was originally developed to treat the Ebola virus, but research was also conducted on its effectiveness as a treatment for COVID-19 as a result of the pandemic. Once it was shown to be effective in clinical trials of hospitalized patients with severe symptoms, the agent was approved and is now being used in the United States, as well as other countries around the world. The formulations of Remdesivir contain 3 percent of the active ingredient and 97 percent of the cyclodextrin derivative that serves as an excipient.

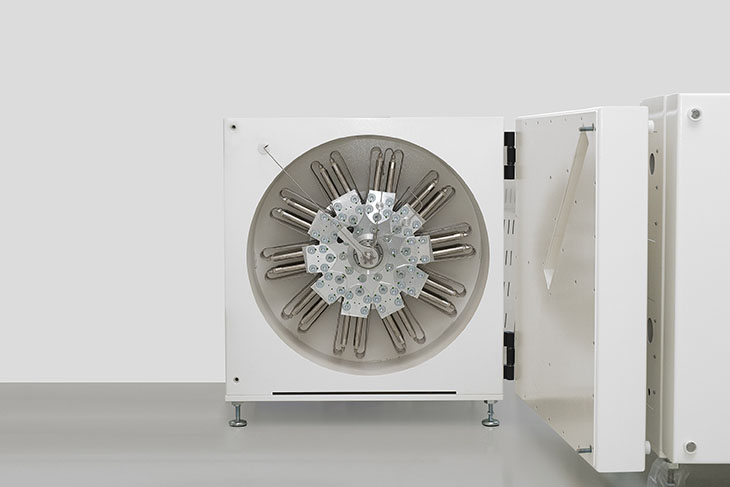

The partnership will combine RotaChrom’s scalable CPC technology with Cyclolab’s knowledge and experience with cyclodextrins. The scalable system that will be utilized for this collaboration includes RotaChrom’s pilot-scale centrifugal partition chromatographic, known as the rCPC, that utilizes an innovative methodology of chromatography where separation occurs between two immiscible liquid phases, offering several advantages compared to more traditional methods. The result is a more purified compound of interest at a lower cost due to increased efficiency and automation.

“While the world anxiously waits for COVID-19 vaccines to be distributed, many are already infected and suffering from this terrible virus,” said RotaChrom CEO László Madarász. “By enhancing the production of a proven drug that has the ability to treat those who are already sick, we could potentially improve lives. We are proud to provide a solution by combining our company’s technologies with Cyclolab to create this much-needed strategic partnership.”

Cyclolab is a company with unparalleled expertise in the manufacturing, design and formulation of cyclodextrins. For this new collaboration, Cyclolab will provide its cyclodextrin-related analytical, formulation and chemistry expertise that spans back to the 1970s. In the three-staged collaboration that kicked off in early 2021, Cyclolab and RotaChrom aim to explore the potential synergies of the companies’ technologies and evaluate how a more economic purification alternative could be discovered.

“Cyclolab is a pioneer and a global leader in cyclodextrin science, and we are delighted to be working with RotaChrom, a unique company with state-of-the-art chromatography capabilities,” said Tamás Sohajda, CEO of Cyclolab. “This strategic collaboration is a tremendous opportunity to create novel discoveries leading to significant added value through pharmaceutical therapies. While there are a handful of published examples on the marriage of these two techniques, no one has ever attempted to bring it to the industrial level. This is our goal now and what can be a better compound to start with than the one that is critically needed in millions of doses? If we could make even a small impact on better availability – either logistically or economically – we would consider it as a huge success and a beginning of a new era in preparative chromatography.”