Increasing separation efficiency by pH adjustment in Centrifugal Partition Chromatography

NewsAn introduction to chromatography

In this series, we will look at the basics of chromatography. We will start with the basics (chromatography process steps this time) and work our way up towards more complex topics, such as Centrifugal Partition Chromatography. Our goal is to make this topic digestible and easy to understand, so that anyone (without a science degree!) can get a grasp of the subject.

Chromatography is the physical methodology of separating a component from a mixture. But this is, of course, only the top of the iceberg. Many different chromatographic methods and techniques exist, and many factors are at play before regarding which purification method is the best for an individual need.

Are you a chromatography expert already? If so, we have more advanced resources for you. Click the green button if you are interested!

Writing with color

Before we jump in to more detailed explanations, it is interesting to mention how chromatography received its name.

It goes back to the early 20th century Russia. Italian-born scientist, Mikhail Tsvet was experimenting with plant pigments (e.g. chlorophyls, carotenes) in 1900, and he realized how the pigments separated into different colored bands after separation.

The word ‘chromatography’ is derived from Greek words chroma (color) and graphein (to write), and so it directly translates to ‘color writing’.

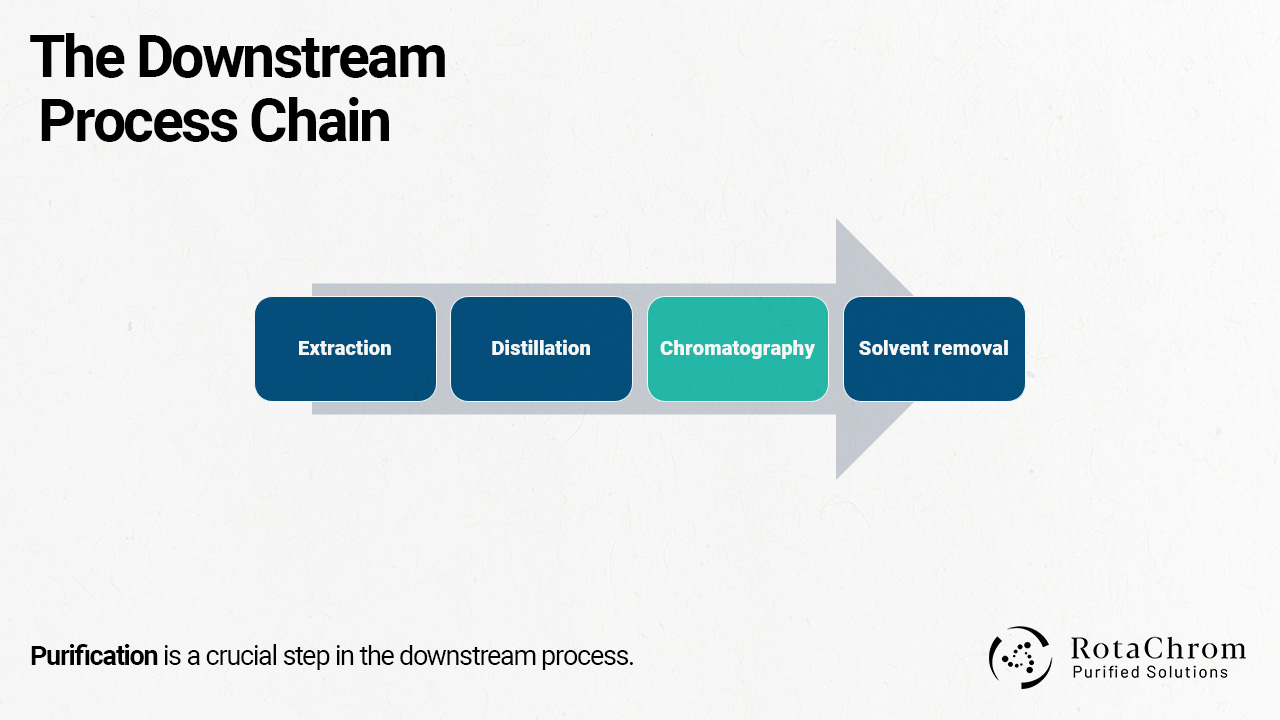

The downstream process chain

The downstream process chain is a series of purification steps, whose goal is to ensure the purity of the product that you receive after going through all the steps. There are several different methods for purification. These range from simple mechanical principles to more complex methodologies.

For simpler processes, purifying with so-called mechanical principles is usually enough. These processes can be:

- Filtration

- Sieving

- Centrifugation

- Dust separation

There are other options available besides the ones mentioned, but this is just to give a brief overview. Either way, once the “heavy lifting” is completed, it is worth refining the purification with more delicate approaches. Chromatography, for example, is one of these more refined methods.

Introducing chromatography in a downstream process can produce much superior end products, which is the main goal of any purification process. In a typical industrial downstream processing chain, chromatography has a place among separation techniques. For a successful purification process, it is important to apply the most selective, most efficient method to get rid of contamination, heavy metals, pesticides.

This is where chromatography becomes relevant.

Chromatography process steps

As mentioned in the introduction, chromatography is the physical methodology of separating a component from a mixture. Or, to phrase it more precisely, chromatography is defined as a physical method of separation in which the components of a mixture to be separated are distributed between two phases, one of which is stationary (stationary phase) while the other (the mobile phase) moves in a definite direction. So, in short, in the chromatographic process components are divided into two media:

- Stationary phase

- Mobile phase

Why are they called stationary and mobile? It comes down to another element of the chromatographic process, the driving force. Due to the driving force (which can be pressure difference, for example) the mobile phase travels through the system and carries sample components with it after the injection of the sample. Components which interact stronger with the stationary phase will be more retained and move through the system slower than components with weaker interactions. This results in a difference in the time it takes for the components to travel through the system. This also creates a difference in separation.

Chromatography process step variations

Chromatography process step variations

The process described so far is, as mentioned before, only the basic description of chromatographic separation. This is just the foundation on which many different chromatographic methods were built. These different methods all capitalize on some aspect (e.g. the driving force used, or the properties of the phases) of the basic chromatographic process and modify or enhance that aspect in some way.

Let’s see some examples how this can be done:

- Chromatographic methods based on the driving force of the mobile phase (e.g., gravity, capillary force, electric field)

- Methods developed based on the nature of the phases used (stationary phase: solid/liquid; mobile phase: gas/liquid/supercritical fluid)

- Utilizing the geometry of the chromatographic device (e.g., planar, column)

- Utilizing the interaction of the solutes with the stationary phase (e.g., physicochemical, biospecific)

Many different chromatographic methodologies exist, for example:

- High-Pressure Liquid Chromatography (HPLC)

- Supercritical Fluid Chromatography (SFC)

- Flash Chromatography

- Centrifugal Partition Chromatography

But again, these are just some of the major examples. All these methodologies have their specific strengths and differences. In the end, the one that you should use comes down to your individual purification needs.

Centrifugal Partition Chromatography Process Steps

Centrifugal Partition Chromarography (CPC) is a complex topic, and we are going to talk about it in detail in a future article. Nonetheless, some of its aspects are relevant for us at this point. As mentioned above, to achieve a successful purification process, it is important to apply the most selective and most efficient method to get rid of contamination, heavy metals, pesticides. Engineers at RotaChrom developed a revolutionary preparative purification instrument called the Industrial Scale Centrifugal Partition Chromatographic (iCPC) device.

This novel system does not require the use of any solid stationary phase (for example silica gel) to perform its precision molecular separation goals. CPC is demonstrably superior to traditional liquid chromatographic methodologies in terms of yield and purity. In addition, RotaChrom’s iCPC platform radically reduced the costs and number of steps associated with downstream method development for a diverse array of purification challenges.

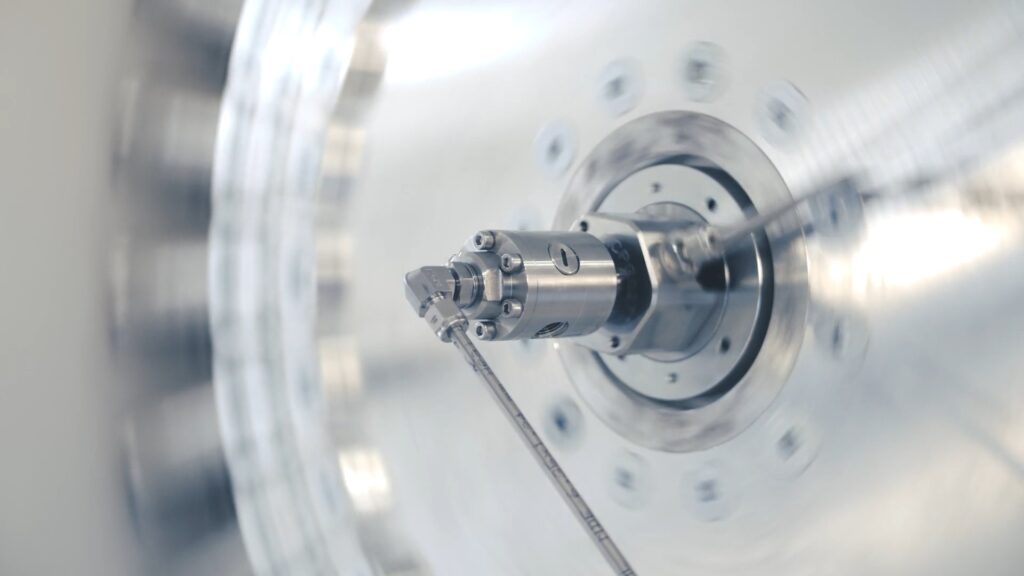

In RotaChrom’s CPC system separation occurs between two immiscible liquid phases. The CPC cells, attached to a large rotor, are filled with the liquid stationary phase and immobilized by a strong centrifugal force. The mobile phase moves through the stationary phase in the form of tiny droplets. The large surface area of the droplets assures optimal mass transfer between the phases.

RotaChrom designed its top performing CPC cells through Computational Fluid Dynamic simulation software. After thousands of simulations, this tool revealed the drawbacks of conventional CPC cell designs and highlighted the unparalleled load capacity and scalable cell design of RotaChrom.

RotaChrom designed its top performing CPC cells through Computational Fluid Dynamic simulation software. After thousands of simulations, this tool revealed the drawbacks of conventional CPC cell designs and highlighted the unparalleled load capacity and scalable cell design of RotaChrom.

In the future, we will go into much more detail about Centrifugal Partition Chromatography process steps. But if you’re curious, take a look at RotaChrom’s Technology page which will give you a head-start in the topic. Or if you’re interested in more in-depth topics related to chromatography, or would like to follow along with this series, make sure to bookmark our News page!

Want to get in touch?

Fill in the form below so our representatives can contact you. We will also let you in on more information on our technology.