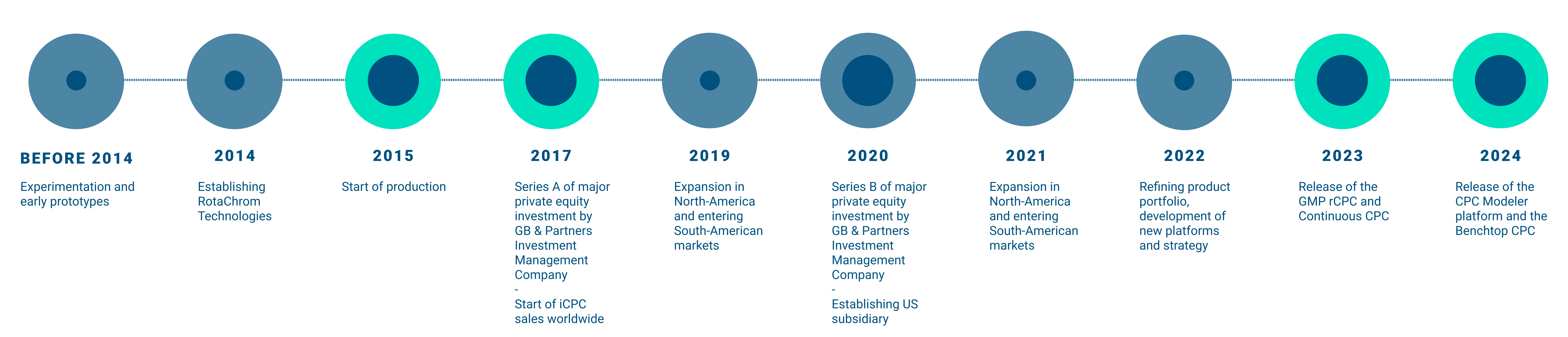

RotaChrom Technologies has developed the world’s first industrial-scale Centrifugal Partition Chromatography (CPC) technology platform. Our instruments have revolutionized purification by providing cost-effective industrial-scale chromatography solutions to customers all over the world in various industries, including pharmaceutical, nutraceutical and botanical extracts. Over the past couple of years, RotaChrom has achieved outstanding growth in the hemp industry by setting the global standard for cannabinoid purification. RotaChrom’s CPC platforms are quintessential applications when looking for a high-purity, high-capacity, cost-effective and environmentally conscious solution. RotaChrom, with its in-house research laboratory employing world class PhD chemists, engineers and leading business professionals on multiple continents, is the best partner in purification.

RotaChrom operates with two main hubs:

- An R&D Laboratory, in which the chemist and chemical engineers develop new methods and work on innovative solutions for diverse CPC applications. These include the isolation, fractionation or remediation of diverse materials, such as natural extracts, APIs, difficult racemates and macromolecules like mRNA or LNP. The research lab has access to characterization tools such as HPLCs equipped with different detectors like UV, CAD, or MS, allowing to monitor the efficiency of the CPC method development at-line and off-line as well. The facility is equipped with multiple CPC units at different scales, to run multiple tests parallel or in hyphenated mode to conduct experiments using MDM (multi-dual-mode) technique. The CPC lab allows the configuration of multiple CPCs to run in tandem to obtain continuous manufacturing scenarios. The laboratory is equipped with all the necessary space and equipment (pH meter, scales, rotary evaps, freeze drying units) to prepare all necessary samples and solvent systems and to run small and pilot scale solvent tests and (residual) solvent removal jobs.

- The Engineering HQ holds most of the mechanical, electrical, process, software and PLC engineers. The engineering and assembly facility houses the product development and production activities under the same roof. The engineering hub offers high capacity computational equipment to run 2D/3D modelling and design tools and conduct CFD and FEA studies, which are related to product development projects. The facility provides space for prototyping- and production related verification, validation and different performance tests. In the test bay, the engineers can pressure test the new designs, conduct preliminary I/O and functional tests, while the QA team conducts FATs (Factory Acceptance Tests) prior releasing the manufactured goods. The location also functions as warehouse to store all parts, spare parts, finished and semi-finished goods. The facility also houses 3rd party (notified body) tests, necessary to demonstrate adherence to diverse regulatory requirements.