Increasing separation efficiency by pH adjustment in Centrifugal Partition Chromatography

NewsIn our previous series ‘An Introduction to Chromatography’ we looked at the main aspects of chromatography. We started with the fundamentals of the subject and then talked about more complex topics. Finally, as we wrap up the series, we arrived at Centrifugal Partition Chromatography (CPC). In this next mini-series, we are going to tackle some more advanced questions related to CPC technology.

Essentials of Centrifugal Partition Chromatography & CPC Technology

Centrifugal Partition Chromatography is a liquid-liquid preparative chromatographic technique. In this method, separation occurs between two immiscible liquid solvent systems. The liquids act as both the stationary and mobile phases. Separation of the sample that is injected is based on the sample component’s varying partition coefficients between the mobile and stationary phases. Partition coefficient (marked with Kd) is the equilibrium constant for the distribution of a compound in a two-phase system.

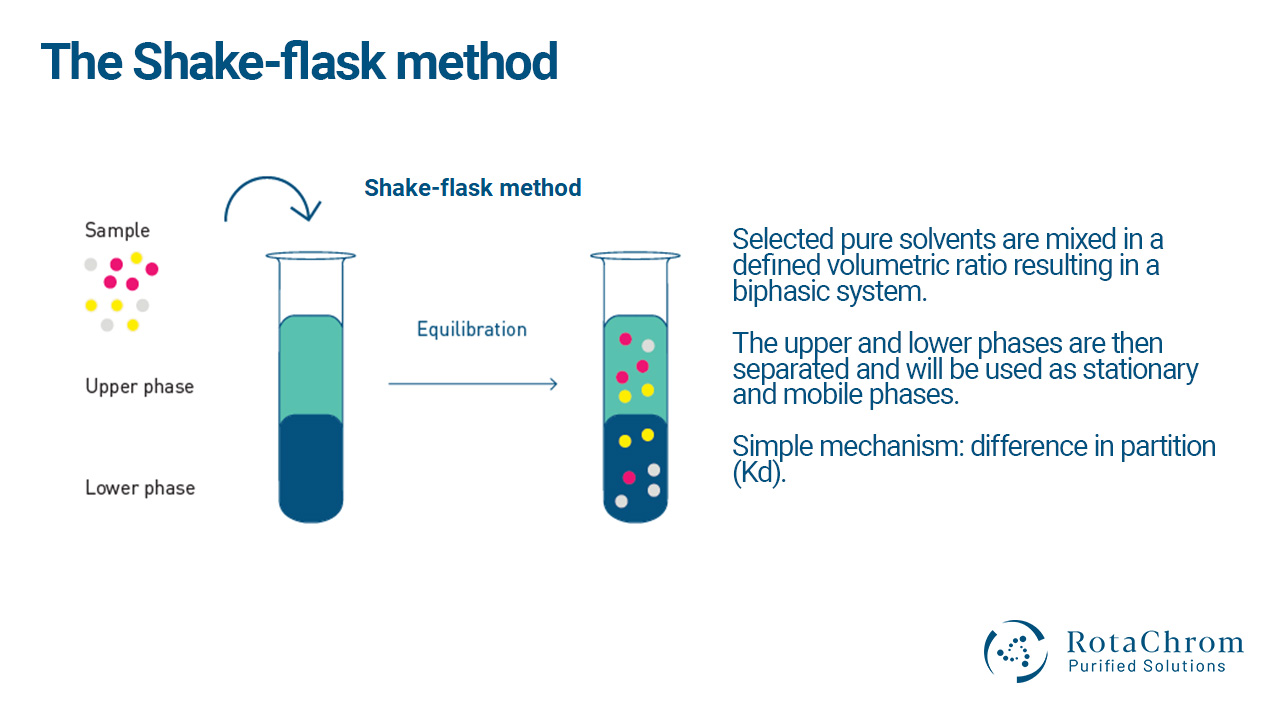

For a specific Compound of Interest (CoI), it is equal to the ratio of its concentration in the stationary phase to its concentration in the mobile phase. To determine the value of Kd, the shake-flask method is routinely performed during method optimization and expressed as the ratio of the concentration of the compound in the upper phase to its concentration in the lower phase by convention. By rule of thumb Kd of the CoI in an optimal solvent system should be preferably in the range of 0.5-2, alternatively 0.2-5.

For a specific Compound of Interest (CoI), it is equal to the ratio of its concentration in the stationary phase to its concentration in the mobile phase. To determine the value of Kd, the shake-flask method is routinely performed during method optimization and expressed as the ratio of the concentration of the compound in the upper phase to its concentration in the lower phase by convention. By rule of thumb Kd of the CoI in an optimal solvent system should be preferably in the range of 0.5-2, alternatively 0.2-5.

This means that the Kd value dictates the amount of time each compound spends in the mobile and stationary phases. Therefore, it also dictates the rate at which each compound travels through the system. Thus, the retention volume (VR) of a given compound is simply calculated by the equation:

VR = VM + Kd × Vs

Here VM and Vs are the mobile and stationary phase volumes, respectively, inside the CPC system. Moreover, the ratio of Kd values determined for a pair of components (separation factor or selectivity; e.g., for CoI and its impurities) clearly predicts their separability in the CPC run.

In the realization of this technique, new techniques could be developed for chromatography. For centrifugal partition chromatography, it was a pattern of CPC cells (columns) interconnected in series by ducts attached to a large rotor filled with the liquid stationary phase. The liquid contained in this series of cells can then be immobilized inside the rotor by a strong centrifugal force.

The other phase of the two-phase system is used as the mobile phase containing the sample to be purified. It is introduced into the rotor under pressure and pumped through the stationary phase in the form of tiny droplets. A valve allows for a change in the direction of flow and therefore the CPC system will work in either ascending mode, where the lighter phase is the mobile phase or in descending mode when the heavier phase is used as the mobile phase.

We cover the ascending and descending modes in more detail in this article.

RotaChrom’s Cell Design

This technique, of course comes, with many benefits. The core advantages of CPC technology over classical, solid support-based preparative liquid chromatography are:

- simplicity of separation mechanism – easy method development and scale-up

- high loadability and recovery – no sample loss due to irreversible adsorption

- no need for solid stationary phase and medium solvent consumption – cost effectiveness.

One of RotaChrom’s most important discoveries was that our extraction cells can be scaled from 10 mm to 100 mm without impacting performance and increasing flows from mL/mins to multiple L/mins. Industrial Scale Centrifugal Partition Chromatography is demonstrably superior to conventional preparative chromatographic techniques in terms of precision performance, adaptability, scalability, and cost effectiveness.

Other advantages include:

Other advantages include:

- Injection plug: responsible for the enhanced and stable droplet dispersion of mobile phase into the stationary phase.

- Tubular cell wall with filling: The circular cross-section not only enables:

- Scalability: Allowing direct scale-up from 2 kg/day (rCPC) to 20 kg/day (iCPC)

- Reliable and robust design with simplified access to the cells for maintainance and cleaning purposes

- Swab-probing reduces issues during cleaning cycles

- Reducing eluent back-mixing

- Collection plug: Our design increases the solvent retention, which increases loading capacity and chromatographic resolution by 20% for the same column size.

CPC technology next steps

In the next article, we are going to tackle the ascending and descending modes of CPC, and the daily operation of an rCPC device.

Want to get in touch?

Fill in the form below so our representatives can contact you. We will also let you in on more information on our technology.